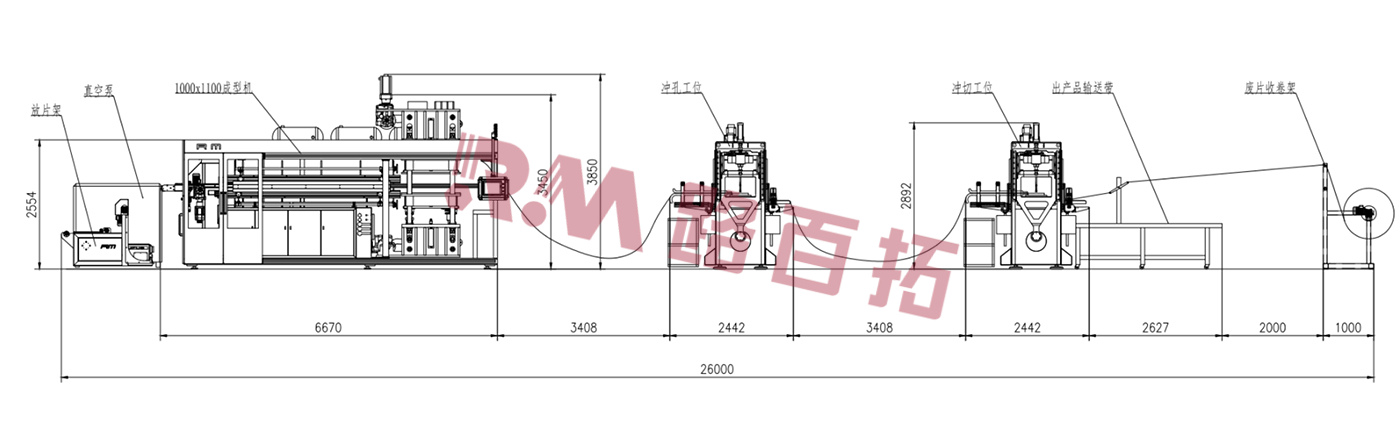

RM-T1011 + GC-7 + GK-7 Thermoforming Machine

Machine Parameters

| ◆Model: | RM-T1011 |

| ◆Max. mould size: | 1100mm×1170mm |

| ◆Max. forming area: | 1000mm×1100mm |

| ◆Min. Forming area: | 560mm×600mm |

| ◆Max. rate of production speed: | ≤25Times/min |

| ◆Max.Forming Height: | 150mm |

| ◆Sheet width(mm): | 560mm-1200mm |

| ◆Mould moving distance: | The stroke≤220mm |

| ◆Max. clamping force: | forming-50T, punching-7T and cutting-7T |

| ◆Power supply: | 300KW(heating power)+100KW(operating power)=400kw |

| ◆Including punching machine 20kw, cutting machine 30kw | |

| ◆Power supply specifications: | AC380v50Hz,4P(100mm2)+1PE(35mm2) |

| ◆Three-wire five-wire system | |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆Reducer: | GNORD |

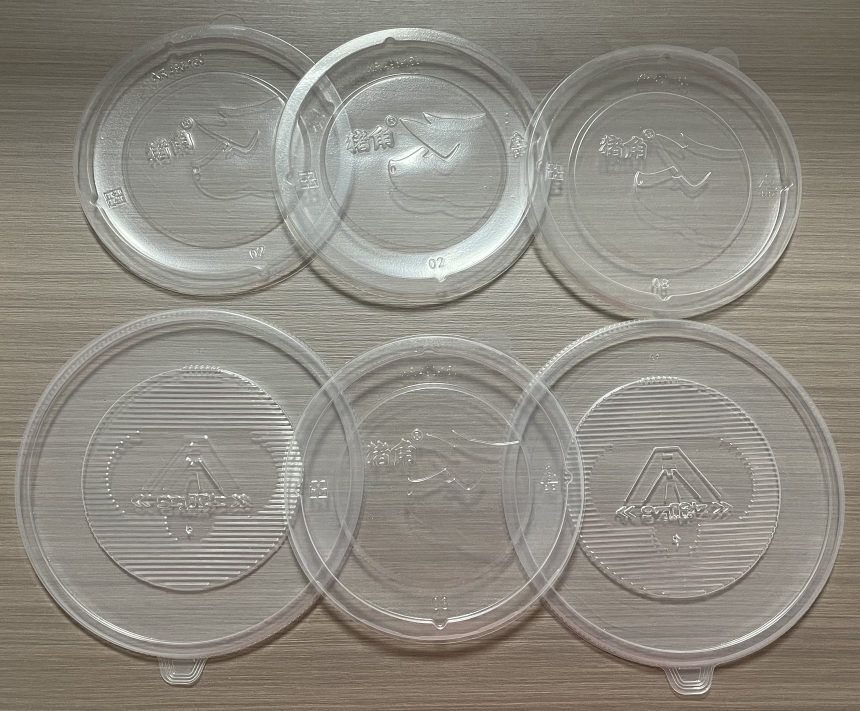

| ◆Application: | trays, containers, boxes, lids, etc. |

| ◆Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Gear, Pump |

| ◆Suitable Material: | PP.PS.PET.CPET.OPS.PLA |

| Max. Mould Dimensions | Clamping Force | Punching Capacity | Cutting Capacity | Max. Forming Height | Max. Air

Pressure |

Dry Cycle Speed | Max. Punching/ Cutting Dimensions | Max. Punching/ Cutting Speed | Suitable Material |

| 1000*1100mm | 50T | 7T | 7T | 150mm | 6 Bar | 35r/min | 1000*320 | 100 spm | PP、HI PS、PET、 PS、PLA |

Product Video

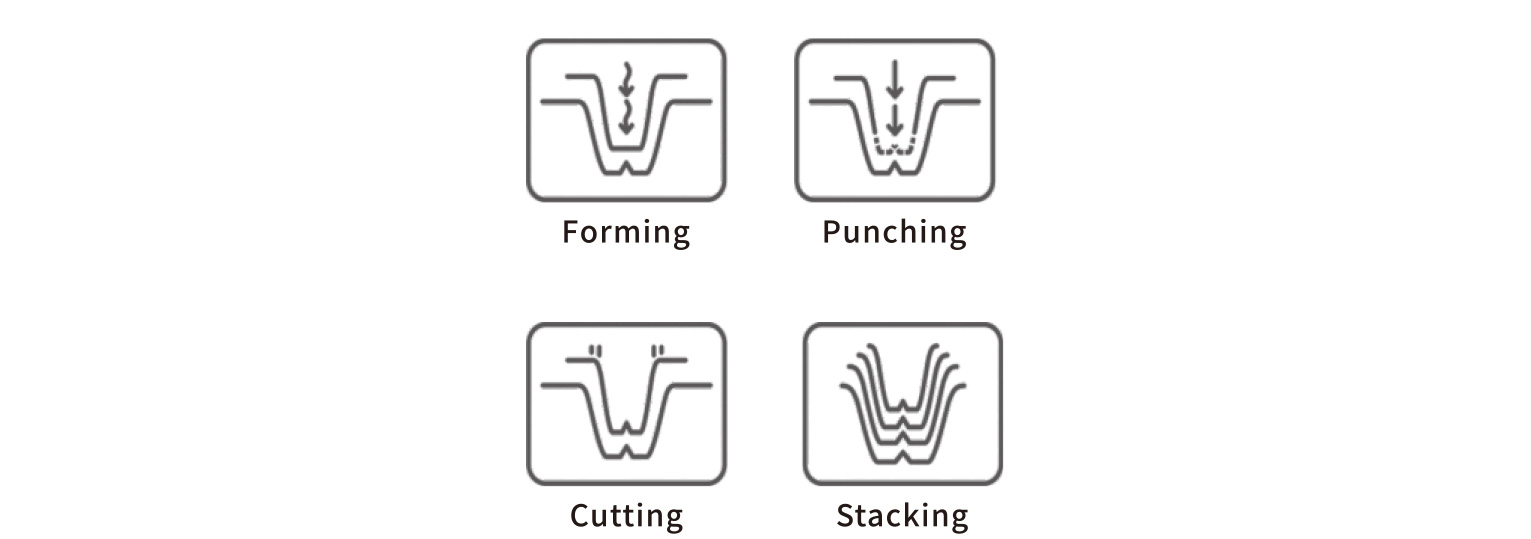

Function Diagram

Main Features

✦ Efficient production: The large format thermoforming machine adopts the working method of a continuous production line, which can continuously and efficiently complete the molding process of the product. Through the automatic control system and high-speed mechanical operation, the production efficiency can be greatly improved to meet the needs of mass production.

✦ Multifunctional operation: the machine has multiple functions such as forming, punching, edge punching and palletizing.

✦ Precise molding and high-quality products: The large-format thermoforming machine adopts advanced molding technology, which can precisely control the heating temperature, pressure and heating time to ensure that the plastic material is fully melted and evenly distributed in the mold, thereby manufacturing products with high surface quality and dimensional accuracy.

✦ Automatic operation and intelligent control: The machine is equipped with a highly automated operating system, which can realize functions such as automatic feeding, automatic forming, automatic punching, automatic edge punching and automatic palletizing. The operation is simple and convenient, reducing manual intervention, greatly improving production efficiency and reducing production costs.

✦ Safety and environmental protection: The large format thermoforming machine is made of high-quality materials, which has good durability and stability. It is also equipped with a safety protection system to ensure the safety of operators. At the same time, the machine has an energy-saving design, which can minimize energy consumption and reduce the impact on the environment.

Application Area

Large format thermoforming machine RM-T1011 thermoforming machine is widely used in the catering industry, food packaging industry and household goods industry. Due to its high efficiency, multi-function and precise features, it can meet the production needs of different industries for plastic products and provide strong support for enterprises to improve production efficiency and product quality.

Tutorial

Equipment Preparation:

To starter your thermoforming machine, secure a reliable large format thermoforming machine RM-T1011 by confirming its secure connection and powering it on. A comprehensive check of the heating, cooling, and pressure systems is essential to verify their normal functionality. Safeguard your production process by meticulously installing the required molds, ensuring they are firmly anchored for smooth operation.

Raw Material Preparation:

Achieving perfection in thermoforming begins with meticulous raw material preparation. Carefully select a plastic sheet best suited for molding, and ensure its size and thickness align with the specific mold requirements. By paying attention to these details, you set the stage for impeccable end products.

Heat Settings:

Unlock the true potential of your thermoforming process by expertly configuring the heating temperature and time through the control panel. Tailor your settings to match the plastic material and mold requirements, achieving optimal results.

Forming - Hole Punching - Edge Punching - Stacking and Palletizing:

Gently place the preheated plastic sheet onto the mold surface, ensuring it is perfectly aligned and free from any wrinkles or distortions that could compromise the forming process.

Initiate the molding process, carefully applying pressure and heat within the specified time frame to shape the plastic sheet precisely into the desired form.

Once the forming is complete, the newly shaped plastic product is left to solidify and cool within the mold, before proceeding to the hole punching, edge punching, and orderly stacking for convenient palletizing.

Take Out the Finished Product:

Inspect each finished product meticulously to ensure it conforms to the required shape and adheres to the established quality standards, making any necessary adjustments as needed.

Cleaning and Maintenance:

Upon completion of the manufacturing process, power down the thermoforming machine and disconnect it from the power source to conserve energy and maintain safety.

Thoroughly clean the molds and equipment to eliminate any residual plastic or debris, preserving the molds' longevity and preventing potential defects in future products.

Implement a regular maintenance schedule to inspect and service various equipment components, guaranteeing that the thermoforming machine remains in optimal working condition, promoting efficiency and longevity for continuous production.