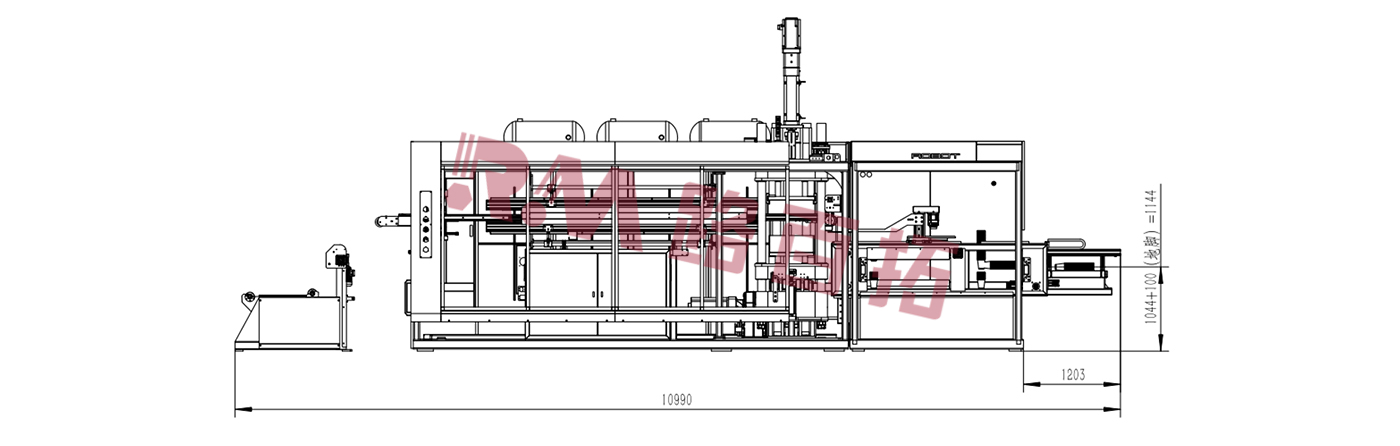

RM 2RH Double Station IMC Thermoforming Machine

Machine Parameters

| ◆Model: | RM-2R |

| ◆Max.Forming Area: | 820*620mm |

| ◆Max.Forming Height: | 80mm |

| ◆Max.Sheet Thickness(mm): | 2mm |

| ◆Max Air Pressure(Bar): | 8 |

| ◆Dry Cycle Speed: | 48/cyl |

| ◆Claping Force: | 65T |

| ◆Voltage: | 380V |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆Reducer: | GNORD |

| ◆Application: | trays, containers, boxes, lids, etc. |

| ◆Core Components: | PLC, Engine, Bearing, Gearbox, Motor, Gear, Pump |

| ◆Suitable Material: | PP.PS.PET.CPET.OPS.PLA |

| Max. Mould Dimensions |

Clamping Force | Dry Cycle Speed | Max. Sheet Thickness |

Max.Foming Height |

Max.Air Pressure |

Suitable Material |

| 820x620mm | 85T | 48/cycle | 2.8mm | 180mm | 8 Bar | PP, PS, PET, CPET, OPS, PLA |

Product Video

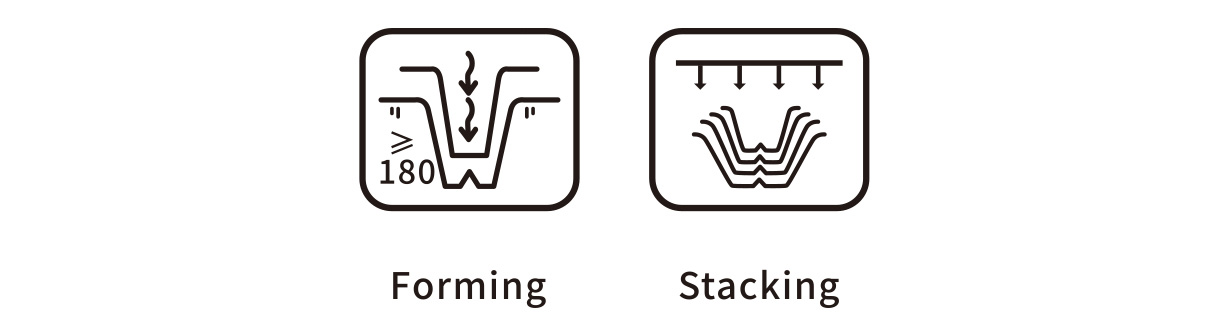

Function Diagram

Main Features

✦ Experience a new level of productivity with our state-of-the-art Automatic High-Speed Forming and Cutting Machine. Featuring a two-station design, it performs forming and cutting simultaneously, significantly boosting production efficiency. The in-die cutting system ensures fast and precise cuts, making the production process more efficient.

✦Our model offers both positive and negative pressure forming capabilities. By applying heat and pressure, the plastic sheet is transformed into the desired product shape. Positive pressure forming guarantees a smooth and consistent product surface, while negative pressure forming ensures the accuracy of concave and convex features, resulting in stable and superior product quality.

✦Equipped with an online palletizing system, our machine achieves automatic stacking of finished products. This streamlined stacking process greatly enhances production efficiency and reduces labor intensity, allowing your team to focus on other critical tasks.

✦Our machine is ideally suited for producing small-height products like disposable sauce cups, plates, and lids. However, it can easily adapt to different product sizes and shapes. By simply changing molds and adjusting parameters, a wide range of products can be manufactured.

✦Invest in efficiency and quality with our Automatic High-Speed Forming and Cutting Machine. Simultaneous forming and cutting, positive and negative pressure capabilities, automated stacking, and flexibility in product production - all in one powerful solution. Stay ahead of the competition and elevate your manufacturing capabilities with our cutting-edge machine!

Application Area

This 2-station thermoforming machine is widely used in food packaging and catering industries. With its advantages and flexibility, it provides enterprises with high-quality and high-efficiency production solutions.

Tutorial

Introduction:

Thermoforming is a versatile and efficient manufacturing process used across various industries. To ensure seamless production and top-notch quality, proper equipment preparation, raw material handling, and maintenance are vital.

Equipment Preparation:

Before commencing production, verify the robust connection and power supply of your 2-station thermoforming machine. Conduct a thorough inspection of the heating, cooling, pressure systems, and other functions to guarantee their normal operation. Securely install the required molds, ensuring they are perfectly aligned to prevent any potential mishaps during the manufacturing process.

Raw Material Preparation:

Begin by selecting a plastic sheet suitable for molding, ensuring it aligns with the project's specific requirements. Pay close attention to the size and thickness, as these factors significantly impact the final product's integrity. With a well-prepared plastic sheet, you lay the foundation for flawless thermoforming results.

Heat Settings:

Open the control panel of your thermoforming machine and set the heating temperature and time . Consider the characteristics of the plastic material and the mold requirements when making these adjustments. Allow the thermoforming machine ample time to reach the set temperature, ensuring the plastic sheet attains the desired softness and moldability for optimal shaping.

Forming - Stacking :

Carefully place the preheated plastic sheet onto the mold surface, ensuring it lies flat and smooth. Initiate the molding process, empowering the mold to apply pressure and heat within the designated time frame, skillfully shaping the plastic sheet into its desired form. Post-forming, let the plastic solidify and cool through the mold, proceeding to the systematic orderly stacking for efficient palletizing.

Take Out the Finished Product:

Thoroughly inspect each finished product to ensure it meets the required shape and adheres to the highest quality standards. This meticulous evaluation guarantees that only flawless creations leave the production line, cementing your reputation for excellence.

Cleaning and Maintenance:

To preserve the efficiency of your thermoforming equipment, adopt a diligent cleaning and maintenance routine. After use, power down the thermoforming machine and disconnect it from the power source. Conduct thorough cleaning of molds and equipment to eliminate any residual plastic or debris. Regularly inspect various equipment components to ensure their optimal functionality, securing uninterrupted productivity.