In the current highly competitive market environment, Rayburn Machinery Co., Ltd., with its mature thermoforming machine technology, provides a strong impetus for the innovative upgrade of plastic products.

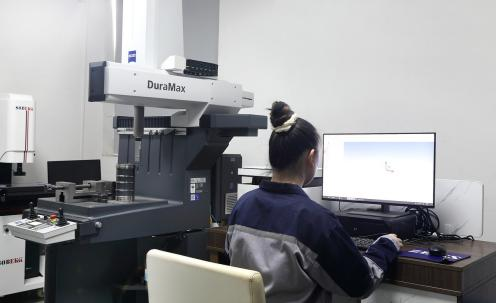

The company's thermoforming machines use the latest automation control technology and high-precision molding molds to efficiently produce complex-shaped plastic products.This advanced technology not only improves product quality and precision, but also shortens production cycles and costs, bringing significant economic benefits to customers.In addition, the machine table processing and assembly are all completed in-house, and it has a self-developed CNC machining center to ensure precision, high machine operation efficiency, and minimal wear, thus ensuring the high quality of the product.

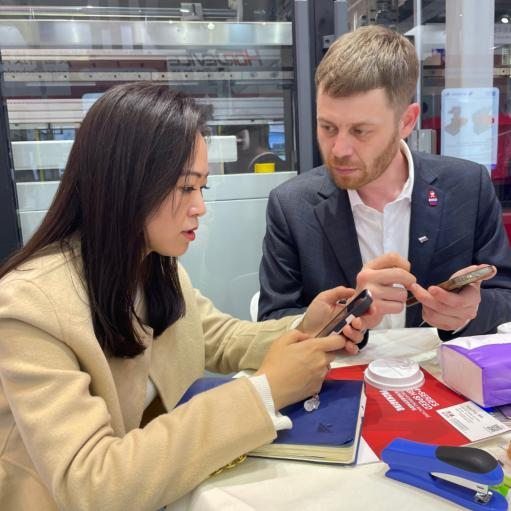

Furthermore, our company also emphasizes cooperation and communication with customers, providing personalized solutions according to their needs. The company's professional team is able to offer customers a one-stop service from product design, mold development to production manufacturing and machine delivery, helping customers achieve the rapid launch of products and the enhancement of market competitiveness.

With the continuous growth of global demand for plastic products and the continuous improvement of product quality requirements, LBT will continue to be committed to the research and development and innovation of thermoforming machine technology, to provide customers with better products and services, and to promote itself in the plastic production industry to keep pace with the times, ensure quality and quantity.

Post time: Jul-05-2024